Introduction

Concrete is the lifeblood of modern infrastructure. From towering skyscrapers in urban skylines to highways that connect entire nations, nearly every structure depends on concrete’s durability and strength. But here’s the truth: concrete alone cannot guarantee safety and quality—it must be tested. That’s where premium concrete testing instruments come in.

Construction projects worldwide face immense pressure to deliver faster, safer, and more sustainable results. Poor-quality testing equipment leads to weak foundations, expensive rework, or even catastrophic failures. For example, reports show that over 30% of global construction project delays stem from material inconsistencies and inadequate testing. This proves that investing in accurate, durable, and compliant testing machines isn’t optional—it’s essential.

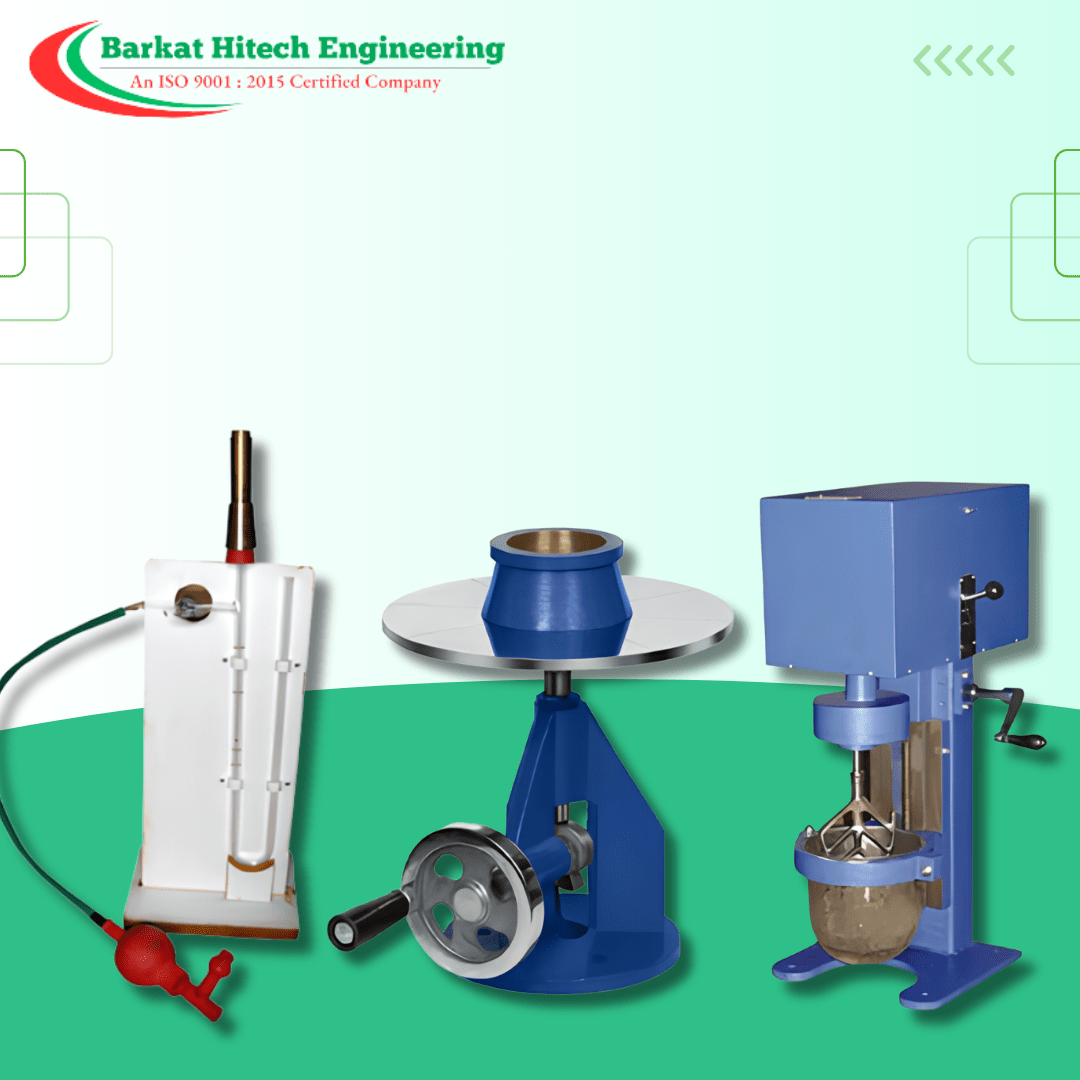

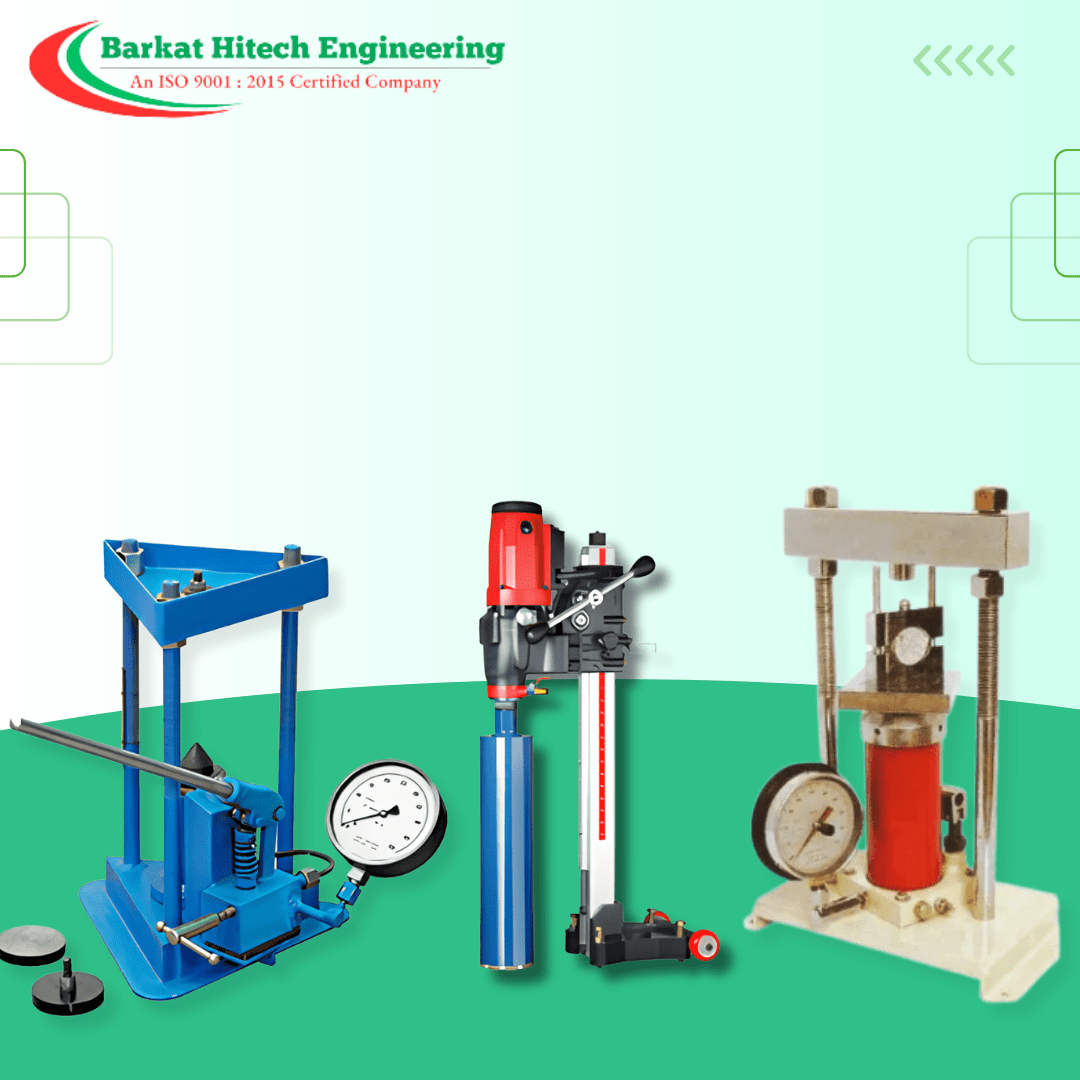

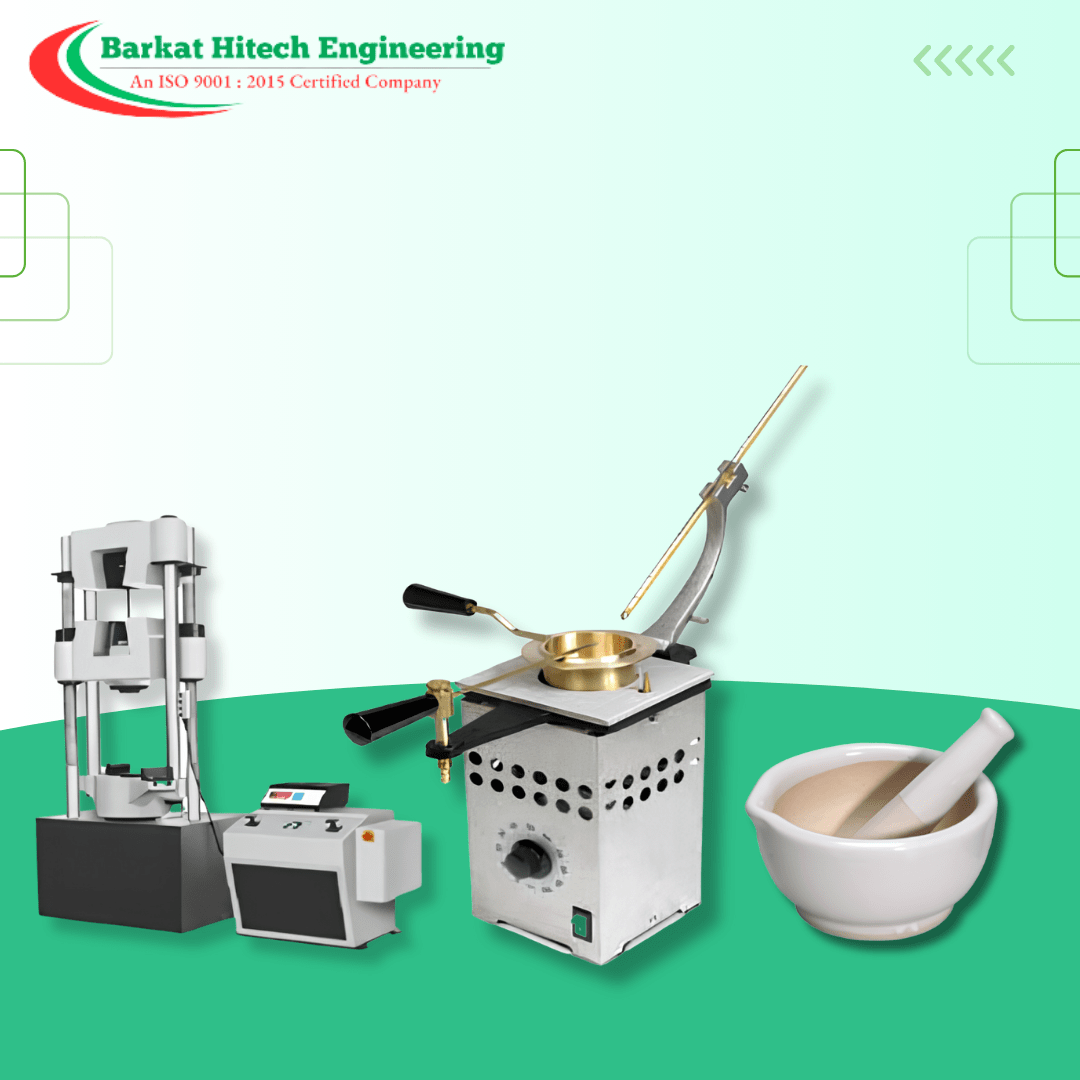

Companies like Barkat Hitech Engineering, a leading concrete testing instrument manufacturer, provide high-precision tools that empower construction firms to deliver projects that stand the test of time.

Let’s explore the 7 powerful reasons construction firms rely on premium instruments, and why cutting corners here is never an option.

1. Unmatched Accuracy for Structural Safety

Why Accuracy Matters

In construction, even a 2–3% margin of error in test results can spell disaster. Weak concrete may lead to cracked walls, leaks in basements, or collapsed bridges. Accuracy in testing defines the safety of a project for decades.

- Low-Grade Instruments: Often miscalibrated, giving inconsistent results.

- Premium Instruments: Calibrated with precision, eliminating guesswork.

For instance, during the construction of the Mumbai Metro, strict concrete strength testing protocols ensured that each segment could withstand the daily stress of thousands of passengers. Premium instruments played a direct role in ensuring long-term safety.

Case Example:

A mid-sized builder in Delhi reported that inaccurate results from low-quality compression testing machines led to three weeks of rework and nearly ₹15 lakhs in losses. After switching to Barkat Hitech Engineering’s calibrated machines, test accuracy improved, and rework was cut by 80%.

Bottom Line: Premium testing equipment doesn’t just measure strength—it safeguards lives and investments.

2. Compliance with Global Quality Standards

The Importance of Standards

Concrete is tested against global benchmarks like IS (Indian Standards), ASTM (American Standards), and BS (British Standards). Failure to comply may result in penalties, project rejection, or blacklisting.

- Cheap Instruments: Rarely comply with calibration standards.

- Premium Instruments: Built to ensure tests meet exacting global norms.

Example:

When building the Chenab Bridge in Jammu & Kashmir (the world’s highest railway bridge), adherence to international concrete standards was non-negotiable. Premium testing instruments were used to validate each phase of construction, ensuring zero compromise.

Compliance also builds trust with clients, government bodies, and private investors—ultimately translating into repeat business and long-term growth.

Bottom Line: Compliance isn’t just a legal necessity—it’s a competitive edge.

3. Durability and Long-Term ROI

Cost vs. Value

Many firms fall into the trap of choosing cheaper instruments to cut costs. But in reality, low-grade machines break down quickly, require frequent repairs, and lead to downtime.

- Premium Machines: Built with cast iron, stainless steel, and high-precision components for durability.

- ROI Advantage: A one-time investment saves lakhs over the equipment’s lifetime.

Case Example:

A Bangalore construction firm that purchased premium equipment from Barkat Hitech Engineering reported 40% savings over five years compared to earlier use of low-grade tools. The reduced downtime allowed them to complete more projects on schedule.

Bottom Line: Premium instruments are not an expense—they’re a long-term asset.

4. Time Efficiency and Faster Project Delivery

The Role of Time

Construction projects run on razor-thin timelines. Testing delays can disrupt supply chains, labor schedules, and contract commitments.

- Outdated Instruments: Slower processing, manual errors.

- Premium Instruments: Faster testing cycles, automation features, and accurate reporting.

Example:

During the construction of the Delhi–Meerut Expressway, premium testing instruments reduced testing time per batch of concrete by 35%, accelerating overall project delivery by several weeks.

Faster results mean quicker approvals, timely completion, and happier clients.

Bottom Line: Time saved in testing = faster delivery and higher profits.

5. Improved Worker Safety

Safety Beyond Helmets

Safety doesn’t just mean protective gear—it begins with the materials themselves. Weak concrete jeopardizes workers during construction and end-users after project completion.

- Premium Testing: Identifies weaknesses before they become hazards.

- Impact: Prevents accidents, legal liabilities, and tragic losses.

Example:

A collapsed flyover in Kolkata (2016) highlighted how poor testing and weak concrete mix can lead to devastating consequences. Premium testing instruments significantly minimize such risks.

By relying on Barkat Hitech Engineering’s advanced testing equipment, construction firms can create not only strong structures but also a safe work environment.

Bottom Line: Safety isn’t negotiable—and premium instruments ensure it.

6. Advanced Data Collection and Reporting

Data-Driven Construction

In today’s world, data is as valuable as cement. Premium instruments are often equipped with digital interfaces, software integration, and automated reporting features.

- Manual Testing: Prone to human error and paperwork overload.

- Premium Machines: Offer instant reports, audit-ready logs, and error-free data.

Example:

For a smart city project in Pune, digital reporting from testing instruments helped stakeholders monitor real-time material strength, reducing disputes between contractors and clients.

Data also supports better planning, forecasting, and quality assurance documentation for future audits.

Bottom Line: Data is the new cement—premium machines help you build with it.

7. Supporting Sustainable and Eco-Friendly Construction

Green Building Revolution

Construction contributes nearly 39% of global CO₂ emissions. The push for sustainability is stronger than ever, and premium instruments play a silent but crucial role.

- Accurate Testing: Ensures the right concrete mix, reducing material waste.

- Durability Advantage: Stronger structures last longer, reducing resource consumption over time.

Example:

LEED-certified green building projects in India rely heavily on premium instruments to achieve certifications, attract eco-conscious clients, and ensure long-term sustainability.

Bottom Line: Premium testing supports eco-friendly construction and corporate responsibility.

Market Trends in Concrete Testing (2025–2030)

- Rise of AI-powered smart testing machines.

- Increased demand for automated, paperless compliance reporting.

- Growth of portable instruments for on-site testing.

- Focus on sustainability in both instruments and construction practices.

Local vs. Imported Instruments: Which Is Better?

- Imported: Higher costs, longer maintenance cycles.

- Local (e.g., Barkat Hitech Engineering): Cost-effective, quick servicing, tailored to regional standards, and better availability of spare parts.

Why Barkat Hitech Engineering?

- Decades of Expertise in precision instruments.

- ISO-certified manufacturing.

- Durable, cast iron–based equipment designed for Indian and global standards.

- Proven partnerships with leading contractors and infrastructure projects.

Conclusion

Construction isn’t just about laying bricks and pouring concrete—it’s about building trust, safety, and sustainability. Premium concrete testing instruments are the foundation of that trust.

By investing in high-precision tools from Barkat Hitech Engineering, construction firms gain:

- Accurate results

- Compliance assurance

- Long-term ROI

- Worker safety

- Data-driven decision-making

- Sustainability advantages

In short, premium instruments don’t just measure concrete strength—they measure the strength of your future projects.

Ready to upgrade your testing lab? Partner with Barkat Hitech Engineering and ensure your projects stand tall for generations.