Introduction

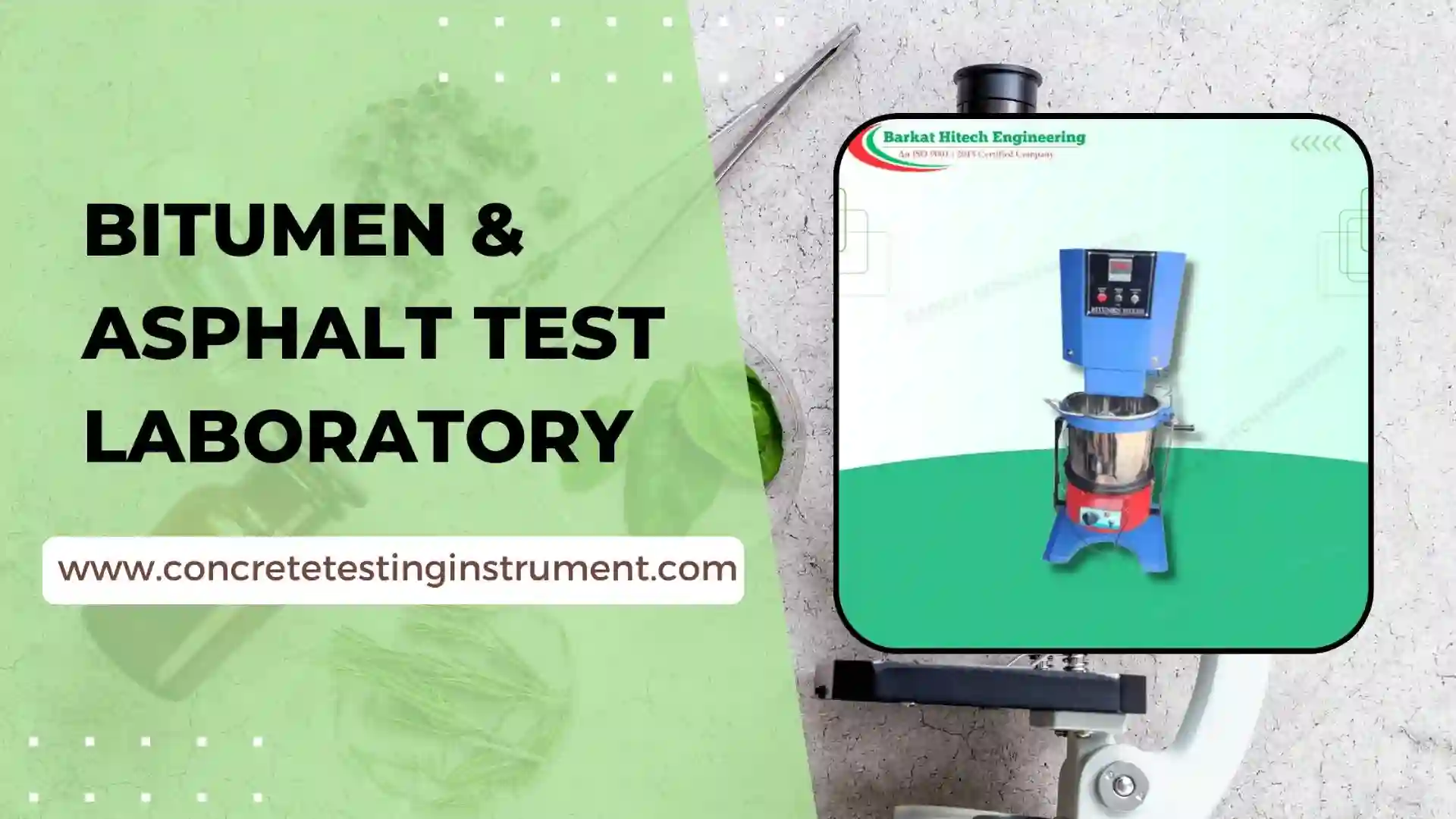

In the field of road construction and infrastructure development, testing the quality of bitumen and asphalt is crucial. Ensuring that materials meet industry standards and safety regulations is essential for building durable and long-lasting roads. If you’re looking for the best bitumen & asphalt test laboratory manufacturer in Delhi, Barket Hitech Engineering is your trusted partner. We specialize in high-precision testing instruments that provide reliable results for road construction projects.

Delhi, as a hub of major infrastructure projects, requires advanced bitumen and asphalt testing equipment to guarantee the durability of roads, highways, and pavements. Testing helps maintain high safety standards and enhances the longevity of constructed surfaces. Barket Hitech Engineering is a leading supplier of bitumen and asphalt testing laboratories in India, offering state-of-the-art solutions tailored to meet the needs of construction companies, contractors, and quality control labs.

What is Bitumen & Asphalt Testing Equipment?

Bitumen and asphalt testing equipment is used to analyze the strength, viscosity, penetration, softening point, and other critical properties of bituminous materials. This testing ensures that asphalt meets standardized specifications for road construction and maintenance.

Types of Bitumen & Asphalt Testing Equipment

- Penetrometer Apparatus – Measures the penetration value of bitumen, indicating its consistency and hardness.

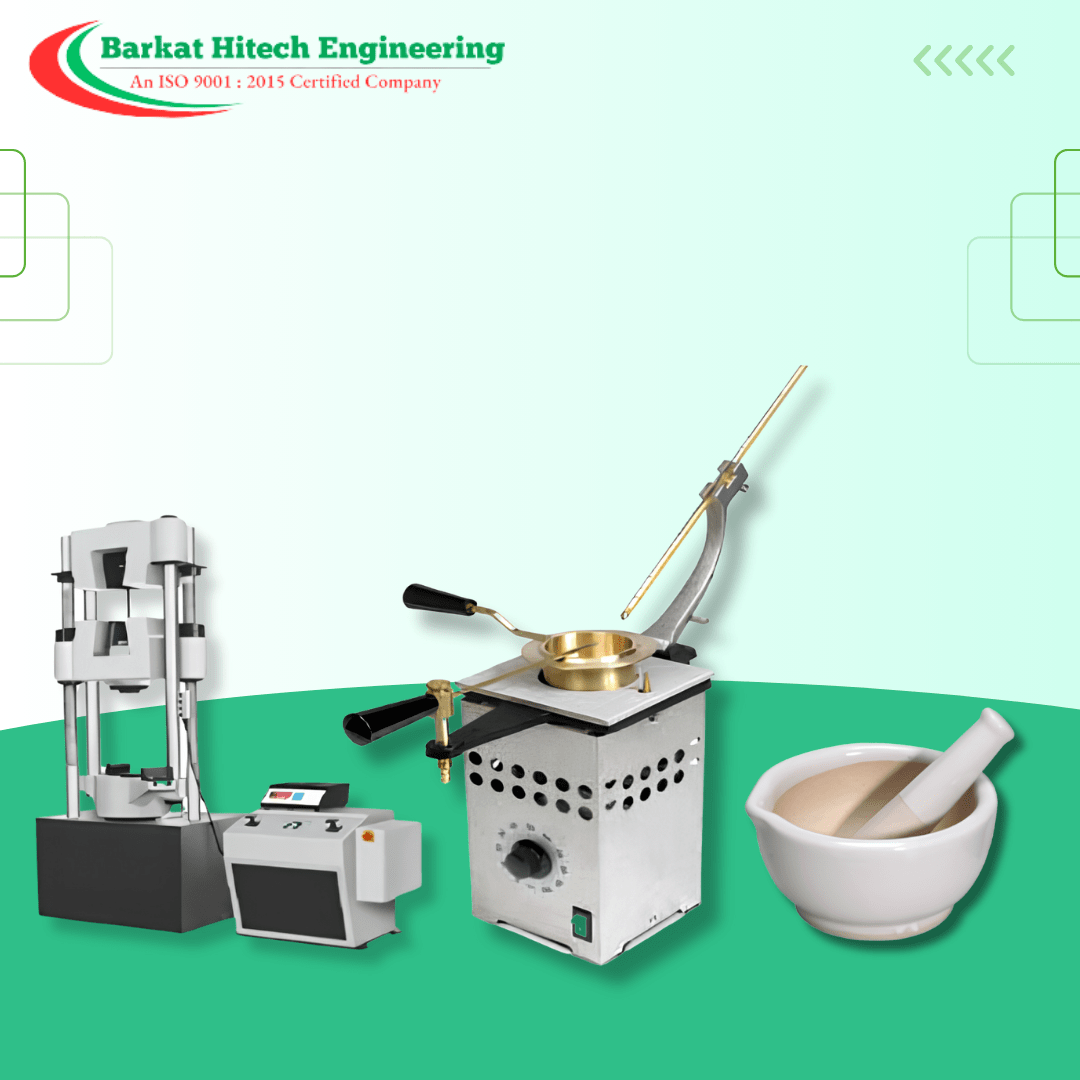

- Softening Point Apparatus – Determines the temperature at which bitumen softens, essential for assessing its suitability for different climates.

- Ductility Testing Machine – Evaluates the elasticity and stretchability of bitumen, which affects road durability.

- Viscometer for Bitumen – Measures the viscosity of bitumen, crucial for determining its flow characteristics.

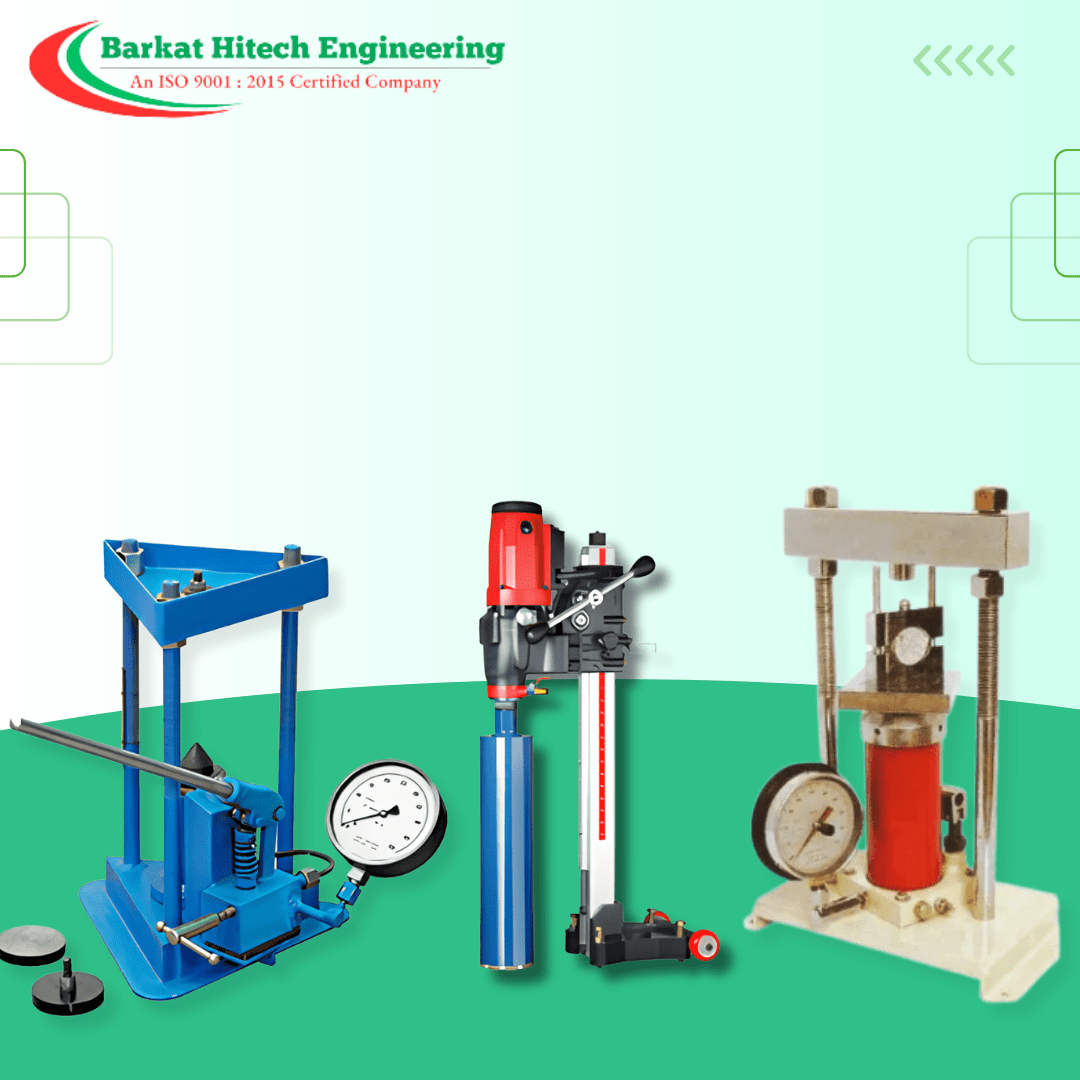

- Marshall Stability Testing Machine – Assesses the stability and flow properties of asphalt mixtures, ensuring they can withstand traffic loads.

- Flash & Fire Point Apparatus – Determines the flammability of bitumen, ensuring safe handling and application.

Importance of Bitumen & Asphalt Testing in Road Construction

Testing bitumen and asphalt is essential for ensuring high-quality, durable, and safe road surfaces. Poor-quality bitumen can lead to road deterioration, potholes, and increased maintenance costs. Some key benefits of bitumen and asphalt testing include:

- Enhanced Road Durability – Ensures that asphalt can withstand heavy traffic and weather conditions.

- Compliance with Standards – Testing confirms compliance with BIS, ASTM, and AASHTO regulations.

- Cost Efficiency – Prevents early road failures, reducing repair and maintenance expenses.

- Environmental Sustainability – Helps optimize material use, minimizing waste and promoting eco-friendly construction practices.

Why Choose Barket Hitech Engineering for Bitumen & Asphalt Testing Equipment?

- Cutting-Edge Technology & Precision Engineering

We manufacture high-precision bitumen and asphalt testing machines designed for accurate and consistent results. Our equipment is built using the latest technology to ensure reliability in every test.

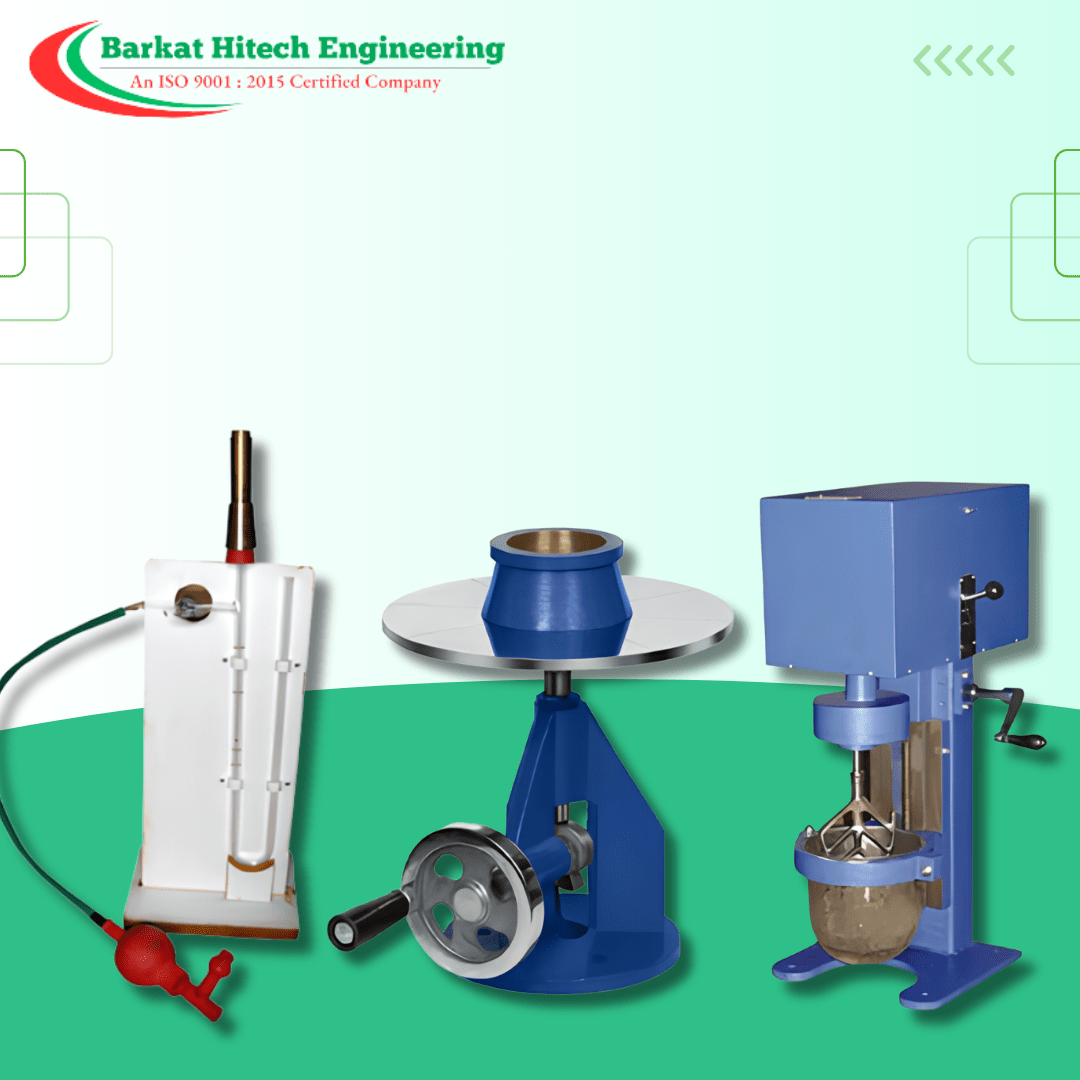

- Comprehensive Range of Testing Instruments

Our product line includes penetration testers, viscosity meters, Marshall stability testers, and softening point apparatus, catering to all asphalt and bitumen quality control needs.

- High Durability & Low Maintenance

Our testing equipment is crafted with robust materials to ensure long-lasting performance with minimal maintenance requirements.

- Dedicated After-Sales Support & Spare Parts Availability

We offer installation, calibration, spare parts, and ongoing support, ensuring that your bitumen and asphalt testing laboratory operates smoothly.

- Compliance with International Standards

Our equipment meets BIS, ASTM, and AASHTO standards, ensuring reliable and industry-compliant testing results.

Top Locations for Bitumen & Asphalt Testing Equipment Manufacturers in Delhi NCR

If you are looking for the best bitumen and asphalt testing equipment supplier in Delhi, consider these industrial hubs:

- Mundka Industrial Area, Delhi – Known for construction material testing manufacturers.

- Bawana Industrial Area, Delhi – A hub for road testing equipment manufacturers.

- Faridabad, Haryana – Home to multiple asphalt and bitumen testing equipment suppliers.

- Gurgaon, Haryana – Offers a range of high-precision bitumen quality testing tools.

- Noida, Uttar Pradesh – A growing center for laboratory and road testing machinery.

Conclusion

Investing in high-quality bitumen and asphalt testing equipment is vital for ensuring safe, durable, and cost-effective road construction. Choosing the right manufacturer, such as Barket Hitech Engineering, guarantees precision, compliance, and long-term reliability.

For the best bitumen and asphalt test laboratory manufacturer in Delhi NCR, contact Barket Hitech Engineering today and explore our comprehensive range of road testing solutions!

Frequently Asked Questions (FAQs)

Q1. What is the price of bitumen testing equipment in Delhi?

Prices depend on the type of equipment. A Marshall stability testing machine may cost between INR 1,00,000 and INR 5,00,000, while a penetrometer is priced around INR 10,000 to INR 50,000.

Q2. Why choose Barket Hitech Engineering for asphalt testing equipment?

We offer high-quality, durable, and industry-compliant testing instruments with exceptional after-sales service.

Q3. What is the purpose of a Marshall stability test?

This test measures the strength and resistance of asphalt mixtures under load, ensuring road durability.

Q4. Can I get customized bitumen testing equipment in Delhi?

Yes, Barket Hitech Engineering provides tailored solutions based on specific testing requirements.

Q5. How do I maintain my asphalt testing equipment?

Regular maintenance includes:

- Periodic calibration of testing machines

- Cleaning and proper storage

- Lubrication of moving parts