Introduction

Rock and aggregate quality is critical in construction, mining, tunneling, and infrastructure projects. Accurate rock testing ensures the stability, safety, and longevity of structures built on or with these materials.

Traditionally, rock testing involved manual measurements, uniaxial compression tests, and visual inspections, which were time-consuming and prone to variability.

With the integration of Artificial Intelligence (AI) and digital simulation, rock testing has entered a new era. Engineers can now predict behavior under load, simulate stress conditions, and optimize material selection, enhancing precision and reliability.

Barkat Hitech Engineering, a leading manufacturer of rock testing instruments, is pioneering this revolution by combining traditional mechanical testing with AI-powered predictive analytics and digital simulations.

The Importance of Precision in Rock Testing

Accurate rock testing impacts:

- Foundations and Earthworks: Predicts load-bearing capacity and settlement characteristics.

- Tunnels and Mining: Ensures safe excavation and slope stability.

- Roads and Pavements: Determines aggregate durability and skid resistance.

- Hydropower and Dams: Evaluates rock stability under hydraulic pressure.

Traditional rock testing methods included:

- Uniaxial compressive strength (UCS) tests

- Point load tests

- Brazilian tensile tests

- Los Angeles abrasion and impact tests

While effective, these methods cannot fully predict complex rock behavior under dynamic or environmental loads, highlighting the need for AI and digital simulation.

How AI is Transforming Rock Testing

1. Predictive Analysis

AI algorithms analyze historical rock test data, material properties, and environmental factors to predict performance under various stress conditions. Benefits include:

- Early detection of potential failures

- Optimization of rock selection for construction

- Reduction in testing time and cost

- Enhanced design reliability

Example: Machine learning models can predict the uniaxial compressive strength of rock from mineral composition, porosity, and density, reducing the need for multiple destructive tests.

2. Automated Data Processing

AI-integrated systems automatically:

- Capture sensor data from compression, shear, and flexural tests

- Identify anomalies or outliers in real-time

- Generate comprehensive reports and graphs

- Provide actionable recommendations for engineers

This automation reduces human error and increases laboratory efficiency.

The Role of Digital Simulation

Digital simulation creates virtual models of rock specimens, allowing engineers to:

- Simulate stress-strain behavior under different load conditions

- Predict fracture patterns and failure modes

- Test scenarios impare ossible or unsafe in real-world conditions

1. Finite Element Analysis (FEA) in Rock Testing

FEA divides rock specimens into small elements, calculating stress and deformation across each. Advantages:

- Simulate large-scale structures without destroying specimens

- Evaluate complex geometries and heterogeneous rock types

- Optimize construction designs based on predictive outcomes

2. Integration with AI

AI algorithms can learn from FEA simulations to:

- Predict rock behavior for new materials

- Recommend testing parameters for optimal results

- Combine lab and simulation data for comprehensive insights

AI and Digital Simulation in Rock Testing Instruments

Modern rock testing machines now incorporate:

- Smart sensors: Load cells, strain gauges, and displacement sensors for real-time data.

- Data acquisition systems: Capture continuous measurements for analysis.

- Simulation software: Create digital twins of rock samples for predictive testing.

- AI algorithms: Identify trends, predict failure, and optimize testing procedures.

Applications:

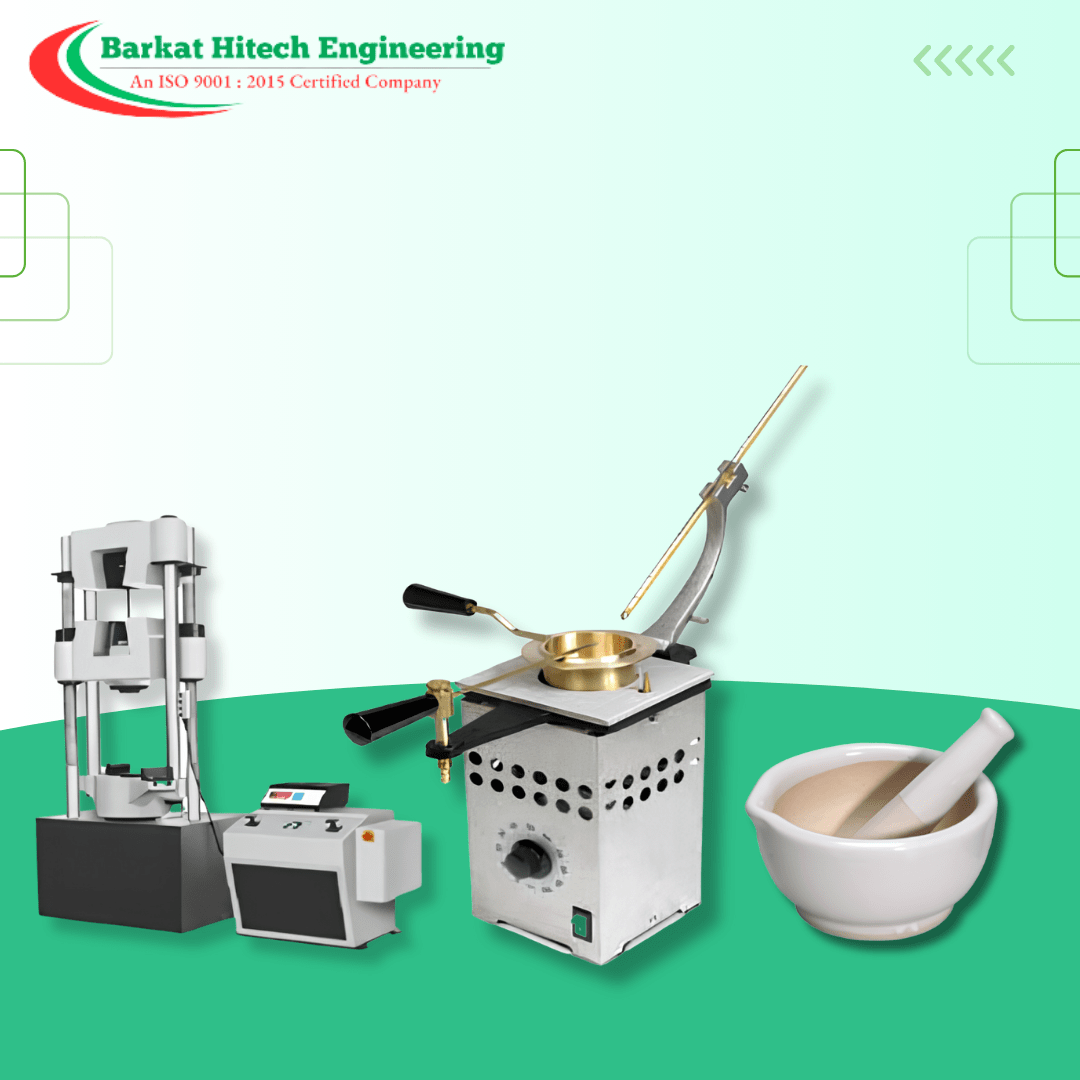

- Uniaxial Compression Tests with Automated Failure Detection

- Triaxial Shear Tests with Digital Stress-Strain Simulation

- Point Load Tests with AI-predicted strength correlations

- Aggregate durability tests combined with predictive modeling

Barkat Hitech Engineering: Leading the AI & Digital Simulation Revolution

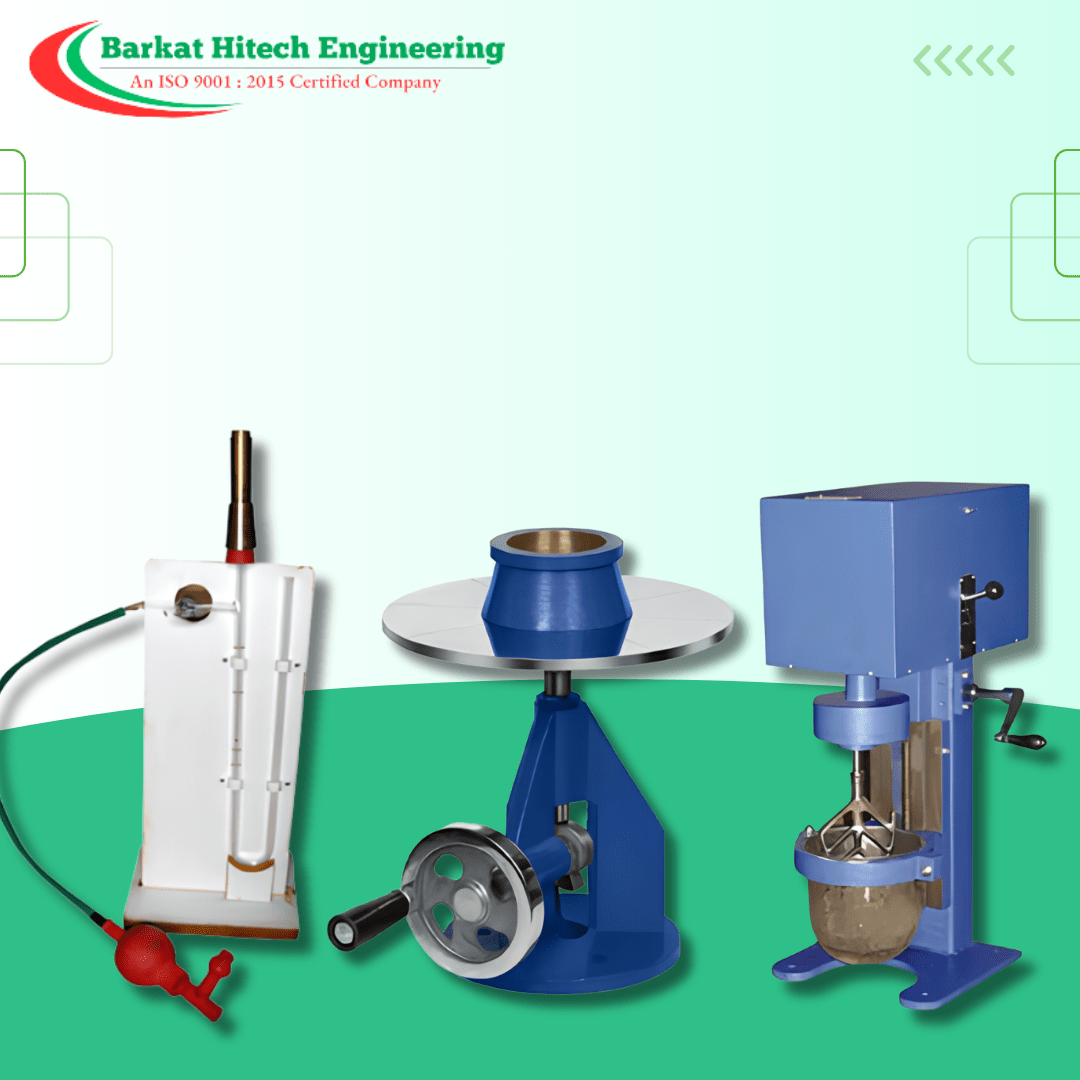

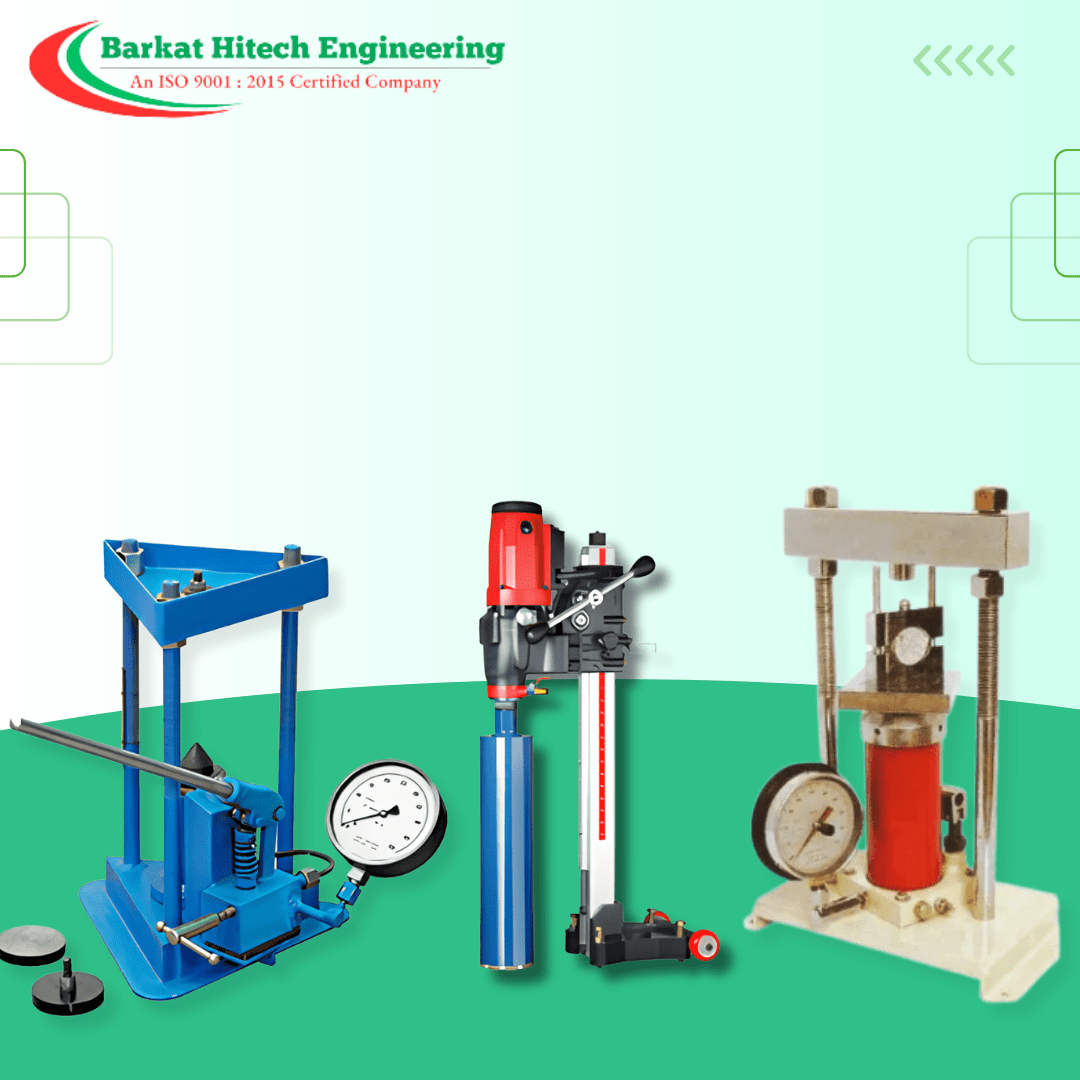

Barkat Hitech Engineering a rock testing instrument manufacturer that integrates smart sensors, AI algorithms, and simulation capabilities:

- Triaxial shear and compression machines with digital load and displacement sensors

- Real-time data acquisition with predictive analysis

- Digital simulation modules for lab and field conditions

- Software dashboards for trend analysis, reporting, and optimization

This approach ensures accuracy, repeatability, and actionable insights, enabling engineers to make better decisions faster.

Real-World Applications

1. Infrastructure Projects

- Highways and bridges require precise knowledge of aggregate and rock strength.

- AI analysis predicts durability under traffic loads, reducing maintenance costs.

2. Mining and Tunneling

- Predictive models identify weak zones in rock strata before excavation.

- Digital simulations help design safer tunnels and reduce operational risks.

3. Research and Development

- AI accelerates testing for new composite rock materials.

- Simulation allows engineers to optimize lab tests, saving time and costs.

Future Trends in Rock Testing

- IoT Integration: Smart rock testing instruments connected to cloud systems for centralized monitoring.

- AI-Enhanced Predictive Models: Combining lab data, field measurements, and environmental factors.

- Digital Twins: Real-time simulation of rock behavior across multiple sites.

- Sustainable Construction: Testing recycled aggregates and engineered rocks for eco-friendly projects.

- Portable Smart Instruments: Field-ready machines with AI for on-site rock evaluation.

Conclusion

The combination of AI and digital simulation is redefining rock testing precision. Traditional methods, while foundational, are being enhanced by predictive analysis, real-time monitoring, and virtual simulations, offering:

- Greater accuracy and reliability

- Reduced time and costs

- Improved safety and predictive capability

- Holistic insights for modern infrastructure projects

Barkat Hitech Engineering is at the forefront of this transformation, providing AI-integrated rock testing machines that deliver precision, efficiency, and actionable intelligence for engineers, laboratories, and construction companies worldwide.